Metal Magic | Coachbuilt Maserati 300S By Hammer Studios

Words Kasper Branski Photography Kasper Branski and Alex Lawrence

My name is Kasper Branski and I'm a Coachbuilder, including all things metal fabrication. I have a metal workshop called Hammer Studios.

Hammer Studios unofficially started sometime in 2013. At the time I was working at Leiter Motor Company (formerly known as Church Green Engineering) in the south-west of England. We were made aware that the company will be closing its doors. Unfortunately, there wasn't enough potential left to take over the company and keep it running so I decided to start off on my own with just a few customers on board.

When it comes to coachbuilding and metal shaping, I am for the most part self-taught. I picked up a few very basic principles and the rest I developed purely through hard work and determination. It was around 2011 where I felt pretty comfortable with heavy fabrication and was very intrigued by shaping sheet metal. I had an idea of how to do it, so I grabbed some metal and a hammer and started making stuff. Through my process, I have learned that there are a lot of things about coachbuilding that you can pretty much only learn by doing it. The fascinating thing about it is that there is no science, it's an art, a feeling for it.

That goes as far back as high school, pretty much nothing apart from shop class interested me at all. I always had a strong interest in all things motoring and had a passion for making things with my own hands. Naturally, the two went together very well. I find it can be a great challenge and also a great reward at the end.

To talk about a few past projects… First and obviously I can start off with the Maserati 300s. I really enjoyed that project as it provided some beautiful shapes to make from a coachbuilding point of view. The car is now completed and lives in Holland as I was made aware by my previous customer.

I also built a historic F3 Emeryson 500, which was a fun and simple body to make but had some really gradual reverse curves in it which were a challenge. A challenge that was reflected in actually driving the car itself which was a 4wd, jap 500 powered, methanol spitting, little rocket without a differential. It was a handful.

I was also involved in some work on an Allard J2. that was powered by a flathead Ford with Ardun ohv conversion heads. The car went on to many hill climb races and was destined for circuit racing.

Back in the days where I was heavily involved with chassis and suspension fabrication, I was the lead welder with a development project which was a titanium chassis for and Ariel Atom. Also at the time, I was making chassis for the BAC mono as well as replica chassis for GTO Engineering including their 250 SWB, and Testerosa Ferarri chassis. At the same company, we had worked closely on completing various projects for Mclaren, Lotus, and ProDrive to name a few.

Amongst all of this big name stuff, I really enjoy building choppers. Notably a current bike I'm building which I was given full control over the designs of every aspect of the bike, and that's been extremely rewarding seeing my concepts come to fruition. I feel bikes are a lot of fun as I can really let my creativity run wild and make things from my own designs. There is unexplainable freedom that building motorcycles have over building cars.

The one that slipped away... A Ferrari P4 replica. I had started making the chassis for it but very, unfortunately, I never got the chance to carry on with it and make the body...

My work method is… unless working with an already predetermined design, I wing it... I like to see the given job start taking some shape, then I can visualize the finished result in my head, and adjust as I go. The flow of lines and components working well together is my primary focus. Also, something I really like to do is aesthetically combine coachbuilding with chassis work and make it look good together rather than two separate elements. In my eyes, a vehicle should be a functional unit, not a bunch of parts thrown together.

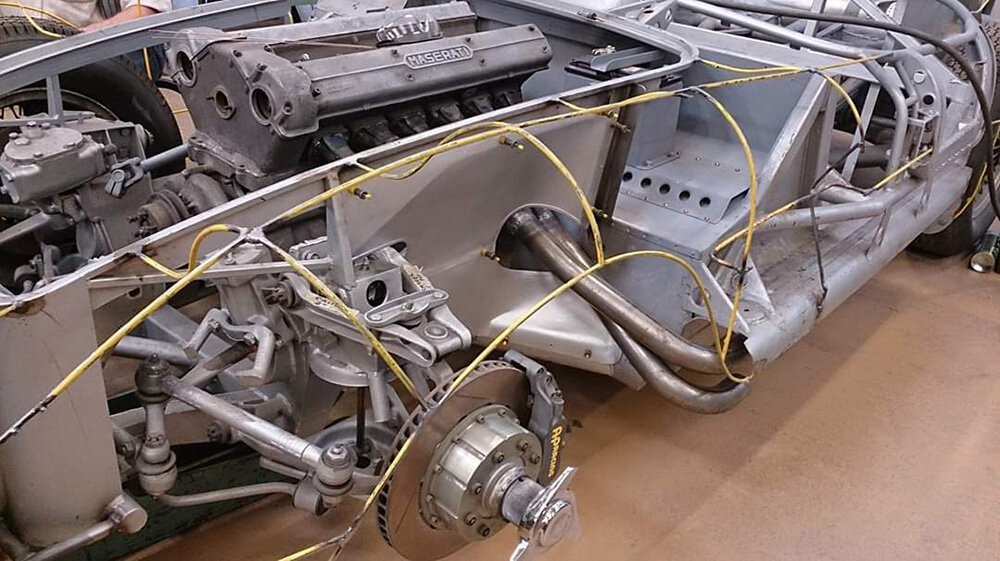

The Maserati build story began whilst I was working at Leiter Motor Company. The rolling chassis was already there, a new owner had taken on the project and with refining all of the close details I started to build it from the existing chassis and up. Being that I joined the company when their very last coachbuilder had retired the whole project was handed over to myself when the customer commissioned the build.

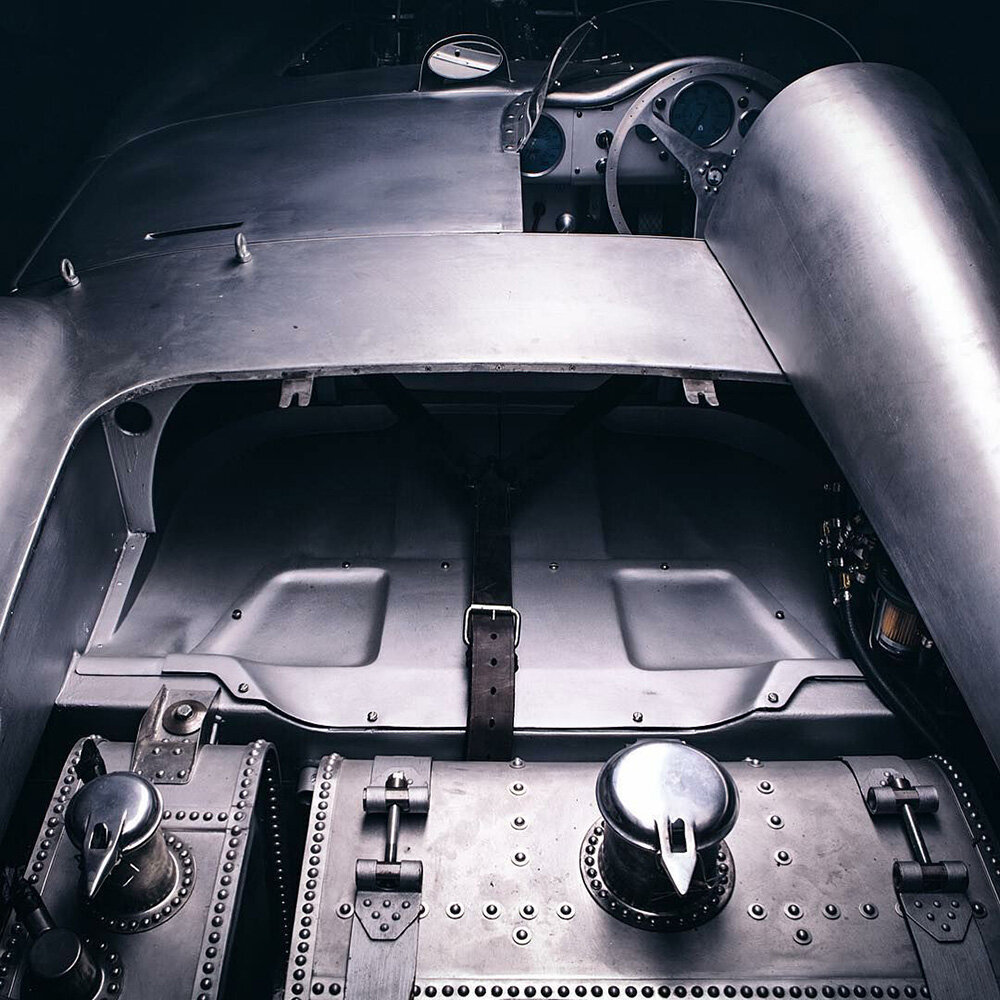

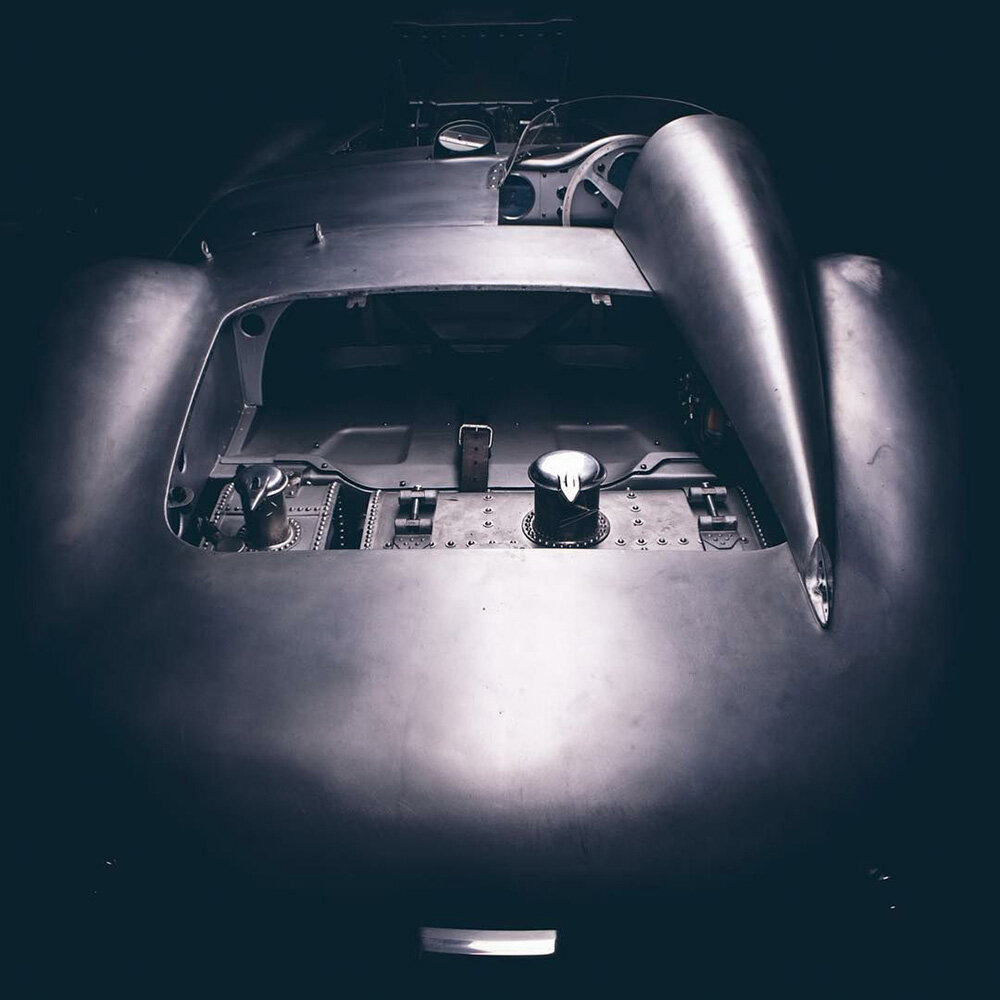

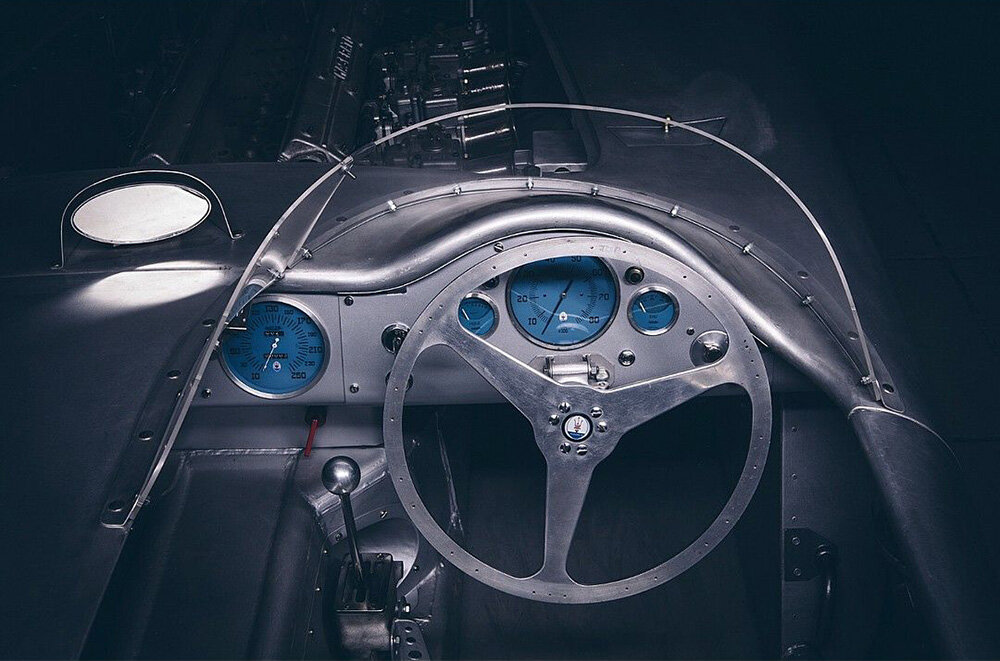

I started out by making a wire-framed buck to use as a guide for the bodywork. By attaching the wireframe directly to the chassis and the framework for the hood and door openings, I was able to build the body directly on the car itself. Which included the grille, headlights and perspex covers, the ducting, the inner panelling, the trunk floor, the latches for removable panels, the perspex windscreen, the tonneau cover, the dashboard, the shifter for the gearbox, and last but not least, the riveted gas and oil tanks, amongst some other small bits and pieces all around the car.

I enjoyed this project because the shapes of the car are super friendly to the English wheel, an absolute pleasure to make the panels. And it was interesting because I was fairly new to Italian cars from that era and the way they were made at the time. I discovered they were in fact very simple from a Coachbuilding standpoint, and very enjoyable to build. Quite the difference from the American cars I was used to working on.

Currently, I'm also building a fully custom chopper which is powered by a big s&s Evo engine. All of the sheet metal work is done in aluminium and will remain polished, the frame chromed, and other components in stainless. A clear display of pure metal, I've ironically named ‘Tequila’.

I also do some work at a local drag racing shop here in Sweden where we build some big tire hp monsters, including a current twin-turbo ‘68 Camaro and a number of Hemi-powered pro mods.

And in the mix of it all, there is also a ‘58 Oldsmobile convertible in restoration, some sheet metal work on a ‘59 Cadillac limo and last but definitely not least, my very own nightmare, a 1930 2-door sedan Buick hot rod which I've have had since being a teenager in Wisconsin, and still not finished...

Time is not enough!

Follow Kasper: @hammer_studios